|

24 / 7

|

|

|||||||||||

Types of our tube bending machines

We produce some different series of benders. And each machine can be made with many automation levels and и additions. It makes no sense to buy the "very-very" completely equipped machine - it can be very-very redundant for your task. Therefore, for a general orientation, it makes sense to read the information below, and to choose the best model for very your task, consult with us.

Our tube bender models differ in purpose and automation level.

Purposes

The main series of our machines are:

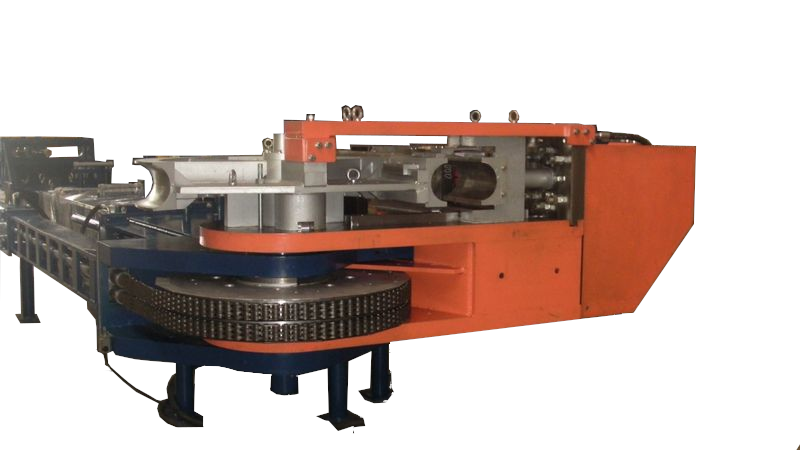

| • | power (T-76, T-90, T-108, T-114) - machines and their parameters | ||

|

machines for the widest applications in energy, common machinery, shipbuilding, other industries, construction, repair, etc.; sufficiently strong and fast at the same time; tube diameter range - up to 114 mm |

||

| • | heavy (T-133, T-159, T-219) - machines and their parameters | ||

|

they are designed for bending large tubes with thick walls (bending thin-walled tubes is also possible); these machines are successfully used in power engineering, nuclear industry, oil and gas industry, etc .; tube diameter range - up to 219 mm (and more on special order) |

||

| • | fast-speed (T-Twin) - machines and their parameters | ||

|

intended for both mass and large-scale production, as well as for single-piece production; these machines work in various industries: the manufacture of metal furniture, car mufflers, sanitary ware, bent frames, building structures, etc. the allow you to bend several tubes at the same time tube diameter range - up to 76 mm |

||

| • | for bending of coils (T-Snake) - machines and their parameters | ||

|

tube bending machines, which could be used as common, but "sharpened" specifically for bending of coils, heated towel rails, etc. tube diameter range - up to 51 mm |

||

In addition to these series, we produce:

-

mobile T-76-MINI - a powerful machine in a design that makes it easy to use right at the repair site; indispensable for ship repair

tube diameter range - up to 76 mm 76 mm

similar machines for larger diameters can be ordered on an individual basis. -

specially over-automated machines T-30A, T-50A, T-90A - machines of very high (about 0.01 mm) accuracy with a large (about 15) number of controlled axes, on which everything is done only by a computer

tube diameter range - up to 90 mm 90 mm -

special (out of series) - designed to solve specific problems, such as bending tubes to large radii, special pipeline configurations, etc.

tube diameter range - widest

Automation levels

The current standards do not provide for a convenient classification of the level of automation of tube bending machines. Therefore, we use our own, convenient for practical use. Now, in the 20s (time passes, and technology develops), we divide machines into the following classes:

-

with manual control - machines on which auxiliary movements (tube installation, clamping, pressing, mandrel movement) are carried out manually;

we do not manufacture especially manual machines, but each of our machines has a manual mode that allows such control

-

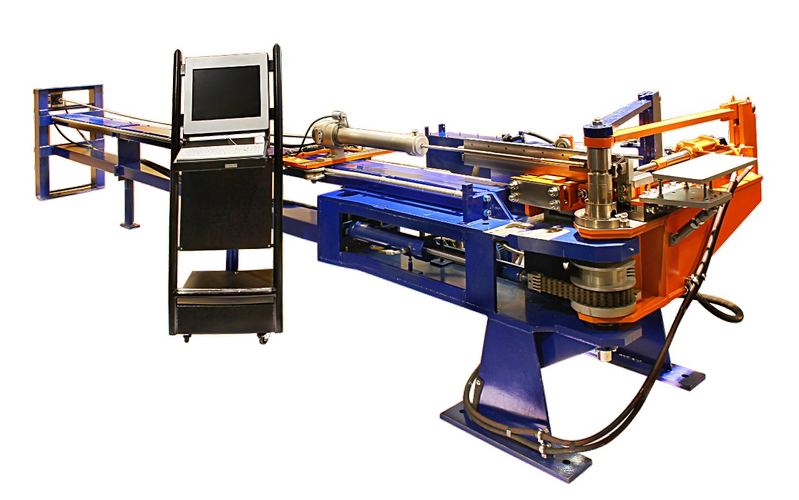

semi-automatic - machines in which the installation and removal of the tube (as well as the movement and rotation of the tube) are performed manually, and the rest of the movements - at the command of the machine;

That is, in order to bend a tube on such a machine, you need to insert the tube, press the remote control button and, after bending, take out the tube, and the machine will do the bending itself according to the specified program.

If it is necessary to make several consecutive bends with the tube turning to another plane, the linear movement of the tube and the tube turning into another plane are also performed manually. For this, the machine has a convenient mechanical stop system.

These machines have an excellent feature/cost ratio - they are convenient for most practical applications.

-

semi-automatic with the indication of tube's movement and rotation - In this case, an indication system is additionally installed on the basic semi-automatic machine.

The movement and rotation of the tube are carried out manually, but the operator can see on the monitor how much the tube has been moved and rotated. And the program can stop the machine if the operator made a mistake.

Before starting bending, the operator clamps the end of the tube in a carriage that moves along the guides. Linear movement and rotation of the tube in space are carried out manually (the operator moves the tube and turns it), while the monitor displays the necessary information for the operator.

For specific tasks, it is possible to reduce the cost of the machine - for example, when flat bending a flat-oval tube, it makes no sense to put an indication of the rotation in space on the machine.

-

semi-automatic with indication and programmable automatic fixers of linear movement and rotation of the tube

To simplify the operator's work and eliminate one's mistakes in moving and turning the tube, the indication system can be additionally equipped with programmable automatic fixers. They are triggered when a certain (set in the program) position of the tube is reached. That is, the operator simply cannot move or turn the tube further than required.

Thus, the work on the machine looks as follow:

- The machine-job is written (just in the native language, no special knowledge in the programming is required).

- The operator installs the tube into the carriage and presses the START button.

- The machine automatically bends the tube (the machine can automatically take into account the spring factor of the tube).

- After that, the operator moves and rotates the tube around its axes. The machine automatically locks (stops) the tube at the position specified in the program.

- So, without stopping, all bends, movements and rotations are made.

It is a very cheap, easy, and comfortable method of producing bent tubes.

-

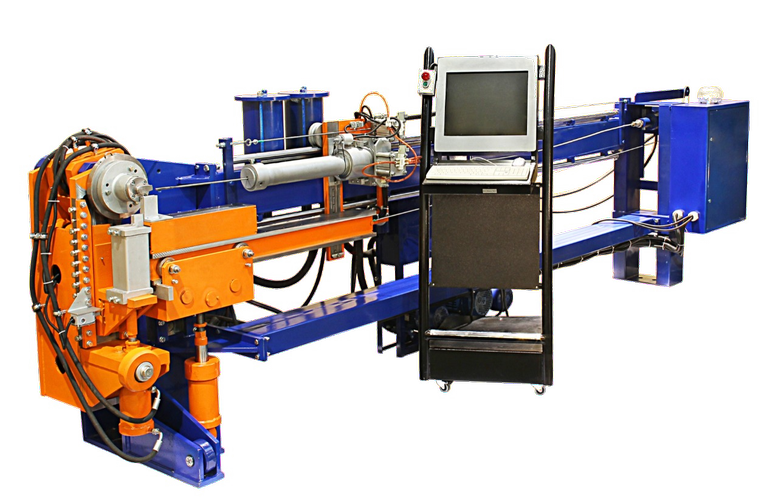

automatic machines - machine with automatic tube's movement and rotation.

The machine will bend the tube, move it, rotate it in space, and so on several times sequentially (as many as indicated in the program).

These machines are advisable to use both for mass bending of various products of complex shape (furniture frames, car mufflers, etc.).

For small-scale and even single bending they reduce the requirements for personnel and their training to a minimum.

Very often these machines are called "CNC tube benders"; we do not use this term because it misleads the buyer - we live in the 21st century and use CNC in all our machines.

-

robotic machines - machines that require human presence only for tool change, maintenance, and repair.

The machines themselves take the tube from the pack (or unwind the pipe from the drum), completely produce the desired product, cut it off if necessary and put it in a container or on a conveyor.

Today these machines are already practical and quickly pay for themselves in mass bending.

The most usual of the machines is semi-automatic. Almost all of our machines are modular. Thus, immediately or later, they can be completed from easiest to fully automatic. We do not impose redundant equipment on the customer and recommend that you consult with us to select the optimal composition of equipment for solving your specific task.

When choosing the degree of automation of the machine, one should proceed from the specific task of the customer, it is impossible to give an unambiguous recipe for all cases.\ But the general trend is towards automatic machines and robotic machines. They allow you to save labor costs and relieve the customer of staffing problems.

Some equipment manufacturers are silent about the fact that some of the capabilities of their machines are optional, that is, available, but for a fee. Often, parameters that actually play an insignificant role in the work are given as an "achievement". It is in the order of things to just keep silent about the lack of certain opportunities. All of these tricks are familiar to us from regular commercial advertisements.

We always set the goal of customer satisfaction, therefore we strive to give a potential customer as much information as possible in a language that is convenient for him.

Thus, you get the opportunity to order the machine exactly in the version that is required for your production.

|

|

|

|

+372 5853 8105 |

|

m@BaltMind.com |

© All rights reserved, 1993 - 2025.

Беларуская

Беларуская

Eesti

Eesti

Suomen

Suomen

Français

Français

Қазақ

Қазақ

Lietuvių

Lietuvių

Latviešu

Latviešu

Polski

Polski

Русский

Русский

Українська

Українська