|

24 / 7

|

|

|||||||||||

What can be bent

On our machines, you can bend almost any profile material, from a simple black steel strip to a complex section tube made of stainless steel, aluminum, copper, titanium, and other materials.

The smallest tube diameter on our machines is not limited, the largest tube diameter is 219 mm. On request, we can make machines for tubes up to 254 mm, 273 mm, and even up to 325 mm (you need to understand that such a machine will already be quite expensive) - our design allows you to scale the machine up to this size.

It is possible to bend tubes of both round and much more complex cross-sections. It is possible to bend very thin tubes. This is not an easy task, but it can be solved with our machines.

Here are examples of what can be produced on our machines:

Bending of round steel tubes for petrol station emergency fences

Bending of round steel tubes for cow farms

Bending of flat-oval tubes

Bending of thin-walled stainless steel tubes

Bending of rectangular tubes

Small radius bending

Bending without straight section

Bending of a complex aluminum profile

Bending of pipes in insulation

Bending of round steel tubes for petrol station emergency fences

|

Photos of fences at the gas station. They must exactly match the requirements of the oil company. |

|

Bending of round steel tubes for cow farms

| The cows are happy - so are the customers! |

|

Bending of flat-oval tubes

|

Bending of thin-walled stainless steel tubes

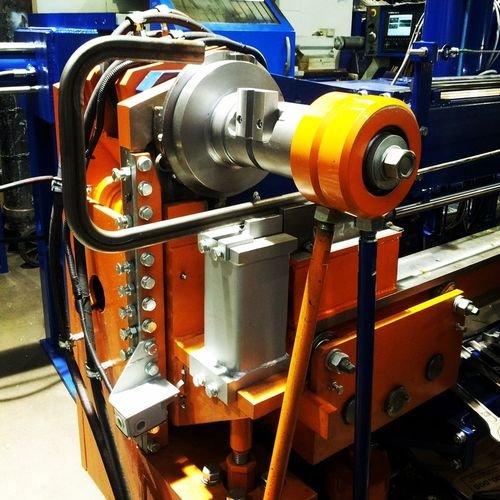

Thin-walled stainless steel tubes can also be perfectly bent on our machines.

In order to bend such a tube qualitatively - especially into small radii - it is necessary to use a special tool.

It is also often necessary to use non-trivial bending modes that provide the proper dynamics.

And the rotation of the bending die must be synchronized with the independent movement of the mandrel.

It is also necessary to provide guaranteed and sufficiently accurate forces that clamp the tube on the disk and hold its free end.

The result is a good bend.

Everyone has seen such products: for example, high-quality heated towel rails decorative and protective covering of off-road vehicles or trucks.

|

Bending of thin-walled stainless steel tube 76 mm in diameter on a T-Twin machine. Such tubes are used, in particular, for decorative and protective covering of off-road vehicles, where excellent surface appearance is very important. |

|

Bending of rectangular tubes

When we bend flat-oval or rectangular tubes, it is very important to determine the required bending quality.

If we are not very interested in the appearance of a bent tube (for example, for internal furniture frames), we can use the so-called directional indentation. However, it is possible to bend a rectangular tube with excellent quality using an appropriate tool. Everyone can see examples of such tubes on sports exercise machines.

|

Small radius bending

For especially small radii, it is necessary to use the so-called boosting, that is, dosed pushing of the tube in the direction of bending. All these efforts and movements must be independent, controlled by the machine, and easily adjusted by the operator.

Bending without straight section

|

Bending of a complex aluminum profile

It is possible to bend completely non-trivial products, such as, for example, a rectangular tube with a cross-section of approximately 207 mm x 75 mm with a complex profile, shown in the photo:

| Bent complex profile. The bending accuracy is about 0.1 mm. |

|

Bending of pipes in insulation

And here is the bending of steel pipes in polymer insulation. An important parameter is that the machine must provide such a bending mode in which not the slightest separation of the braid from the pipe surface will occur.

Of course, when bending, we use the most modern tools, including various kinds of mandrels and wipers.

We can supply equipment both in a simple design and in designs that provide enhanced capabilities for high-quality bending of complex products.

Even if your task seems difficult to you, if you think that it cannot be solved on serial machines, contact us and we will think about what we can offer you taking into account your cost/benefit requirements.

Our goal is to give you the technical ability to commercially bend any product you need, from the simplest to the most complex.

You need good tube bending machines - contact us right now and ask any questions.

|

|

|

|

+372 5853 8105 |

|

m@bend.tube |

© All rights reserved, 1993 - 2024.

Eesti

Eesti

Français

Français

Русский

Русский